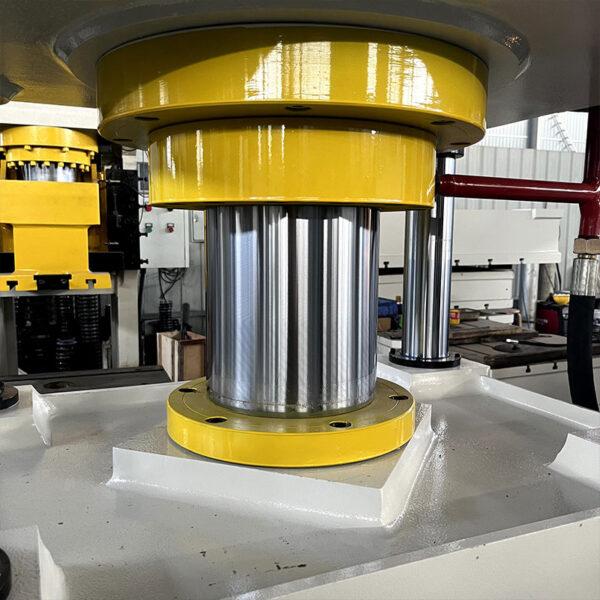

160 Ton Hydraulic Press Vulcanizer Rubber & Fiberglass Molding Machine

Technical Specifications

-

Rated Pressure: 160 Tons / 352,740 lbs

-

Table Size: 700×700mm / 27.56″×27.56″

-

Daylight Opening: 650mm / 25.59″

-

Stroke: 200mm / 7.87″

-

Temp. Range: Ambient~200°C / 68°F~392°F

-

Motor Power: Customized

-

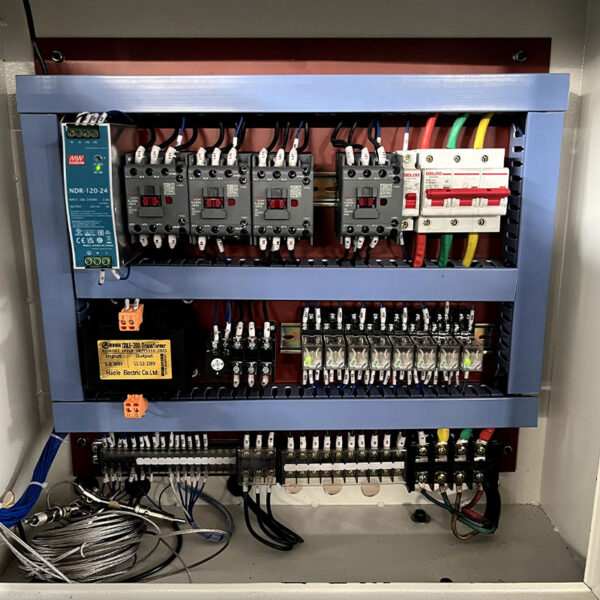

Voltage: 380V 3-Phase

-

Control System: PLC Touchscreen + Temp. Module